Products Description

High carbon ferrochrome is mainly used in stainless steel production, with a chromium content of about 16% in 200 series stainless steel, about 25% in 300 series stainless steel, and about 14% in 400 series stainless steel. The 300 series stainless steel with high demand for ferrochrome is also a major product in stainless steel production.

Used as an alloying agent for ball bearing steel, tool steel, and high-speed steel with high carbon content, to improve the hardenability of steel, increase its wear resistance and hardness; Used as an additive for cast iron to improve its wear resistance and hardness, while also giving it good heat resistance; Used as chromium containing raw materials for the production of silicon chromium alloys and medium, low, and micro carbon chromium iron using slag free method; Used as chromium containing raw materials for electrolytic production of metallic chromium; Used as a raw material for smelting stainless steel by oxygen blowing method.

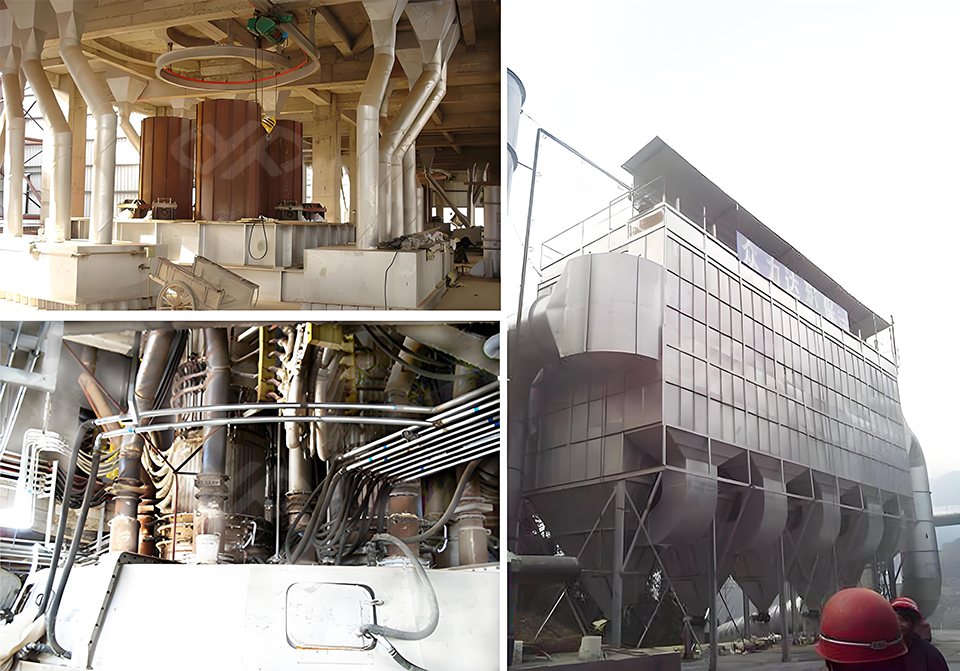

The smelting methods of high carbon ferrochrome include blast furnace method, electric furnace method, plasma furnace method, etc. The use of blast furnaces can only produce special pig iron with chromium content of about 30%. As of 2012, high carbon ferrochrome with high chromium content was mostly smelted using the flux method in a submerged arc furnace.

The basic principle of smelting high carbon ferrochrome by electric furnace method is to reduce the oxides of chromium and iron in chromite ore with carbon. The starting temperature for carbon reduction of chromium oxide to generate Cr2C2 is 1373K, the starting temperature for the reaction to generate Cr7C3 is 1403K, and the starting temperature for the reaction to reduce chromium is 1523K. Therefore, when carbon reduction of chromium ore, chromium carbides are obtained, rather than metallic chromium. The carbon content in ferrochrome depends on the reaction temperature. It is easier to generate carbides with higher carbon content than those with lower carbon content.